Reinforcement steel (rebar) is at the heart of every concrete structure.

Concrete is exceptionally strong in compression but naturally weak in tension — and this weakness is compensated by steel reinforcement.

Properly designed and processed rebar directly determines the strength, durability, and long-term performance of any building or infrastructure project.

Source: Wikipedia – Rebar / Reinforcement Steel

https://en.wikipedia.org/wiki/Rebar

But in today’s construction world, the real competitive advantage doesn’t come from sourcing steel — it comes from processing it with accuracy, consistency, and speed.

🧩 WHY REBAR PROCESSING QUALITY MATTERS MORE THAN EVER

Cutting and bending rebar may seem like simple fabrication steps, but the consequences of poor processing can be severe.

Common Processing Problems

-

Incorrect cutting lengths → Increased waste and project cost

-

Wrong bending angle or radius → Reduced structural reliability

-

Slow manual processing → Project delays and labor inefficiency

-

Inconsistent production → Misalignment, rework, and downtime

Global construction terminology emphasizes one clear truth:

Cutting precision and bending accuracy define the final quality of reinforced concrete.

Source: Shipping & Commodity Academy – Rebar Terminology

https://shippingandcommodityacademy.com/blog/learn-the-jargon-of-the-rebar-industry-essential-terms-for-construction-professionals/

Large-scale projects, high-rise buildings, and precast facilities rely on thousands of precisely fabricated rebar elements. A single error can multiply across the entire structure.

🔍 GOOD STEEL CAN BE RUINED BY POOR PROCESSING

Even the highest-grade steel becomes ineffective when processed incorrectly.

RebarPeople explains:

“Wrong bending radius or inaccurate cutting reduces structural reliability and leads to material wastage.”

Source: RebarPeople – Rebaring & Bar Bending

https://rebarpeople.com/what-is-rebaring-and-bar-bending

This proves that processing quality is as important as the steel itself.

Poorly processed rebar can lead to:

-

Weak structural capacity

-

Poor fit inside formworks

-

Increased structural vibration

-

Higher crack risk

-

Reduced building lifespan

In critical components such as beams, columns, retaining walls, tunnels, and foundations, precision is mandatory.

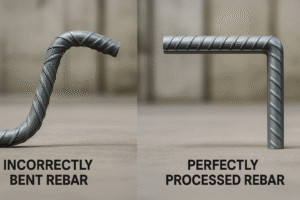

Left side: incorrectly bent rebar with wrong radius, deformities, and uneven angles.

Right side: perfectly processed rebar with accurate bending, clean angles, and smooth surface.

🧱 WHY PRECISE PROCESSING MATTERS (ADDITIONAL TECHNICAL INSIGHTS)

Trusted international engineering sources highlight several key technical reasons why accuracy is essential:

1️⃣ American Concrete Institute (ACI) – Rebar Detailing Standards

ACI 315 and ACI 318 emphasize:

-

Exact bending dimensions

-

Minimum bend diameters

-

Hook angle accuracy

-

Avoiding over-bending

-

Placement tolerances

Incorrect bending directly violates structural safety codes.

Source: American Concrete Institute – ACI 315 Manual

https://www.concrete.org

2️⃣ The Constructor – Cutting & Bending Issues

TheConstructor.org reports that manual cutting often results in:

-

Dimensional deviations

-

Uneven spacing

-

Excessive steel waste

Source: TheConstructor – Reinforcement Cutting & Bending

https://theconstructor.org

3️⃣ CivilJungle – Cost & Efficiency Benefits

A proper bar bending schedule (BBS):

-

Reduces steel usage by 10–15%

-

Minimizes onsite cutting errors

-

Ensures compliance with structural design

Source: CivilJungle – Bar Bending Guide

https://civiljungle.com

4️⃣ EngineeringCivil.com – Manual vs. Machine Comparison

Manual processing:

-

Slow

-

Operator-dependent

-

High error possibility

Machine processing:

-

Uniform precision

-

Faster cycles

-

Lower labor cost

-

Higher safety

Source: EngineeringCivil – Rebar Processing Methods

https://www.engineeringcivil.com

🚀 GOOD REBAR = ACCURATELY PROCESSED REBAR

Modern construction requirements cannot be met with traditional manual techniques.

Automated machinery provides:

-

±1° bending precision

-

High repetition accuracy

-

Faster mass production

-

Zero operator variability

-

Lower operational costs

-

Reduced material waste

Source: Bhadani’s Recorded Lectures – Bar Bending Overview

https://www.bhadanisrecordedlectures.com/blog/overview-of-bar-bending

These capabilities are now considered essential industry standards.

🟧 ENSURING THIS LEVEL OF QUALITY STARTS WITH THE RIGHT MACHINERY

LUXSENSE REBAR CUTTING & BENDING SOLUTIONS

If your business depends on rebar, precision should never be compromised — and choosing the right machine determines your results.

LuxSense provides high-performance solutions for:

-

Rebar Service Centers

-

Precast & Prefabrication Factories

-

Construction Companies

-

Steel Fixing Teams

-

Rebar Distributors

-

Stirrup Manufacturers

-

Infrastructure Contractors

Our solutions include:

🔹 Rebar Cutting Machines

High-strength blades, fast cycle times, CE-certified systems.

🔹 Rebar Bending Machines

Heavy-duty disc platforms, accurate programming, long service life.

🔹 Automatic Stirrup Benders

Servo-driven accuracy for mass stirrup production.

🔹 Industrial-Type Processing Lines

High-volume, high-speed efficiency for fabrication centers.

🔹 Portable Site-Type Solutions

Compact, reliable rebar processing for on-site use.

All LuxSense machines feature:

✔ CE Certification

✔ Heavy-duty build

✔ High precision engineering

✔ Long service life

✔ Turkish manufacturing excellence

✔ Expert after-sales support

🎯 Strong structures start with well-processed rebar — and LuxSense makes that possible.

Project performance, construction speed, and long-term durability all begin with precision.

With LuxSense, every bend and every cut meets the highest standards of structural safety.

📞 Talk to Us on WhatsApp

If you would like to discuss which rebar processing system best fits your projects, you can contact us directly on WhatsApp:

click here to start a conversation: Chat on WhatsApp

🔘 Explore LuxSense Rebar Machines

You can also review our rebar cutting and bending solutions on our website:

➡️ Explore LuxSense Rebar Machines: Explore Rebar Machines